ACTIVE MAGNETIC RANGING

SOLUTION MINING • COAL BED METHANE • HDD

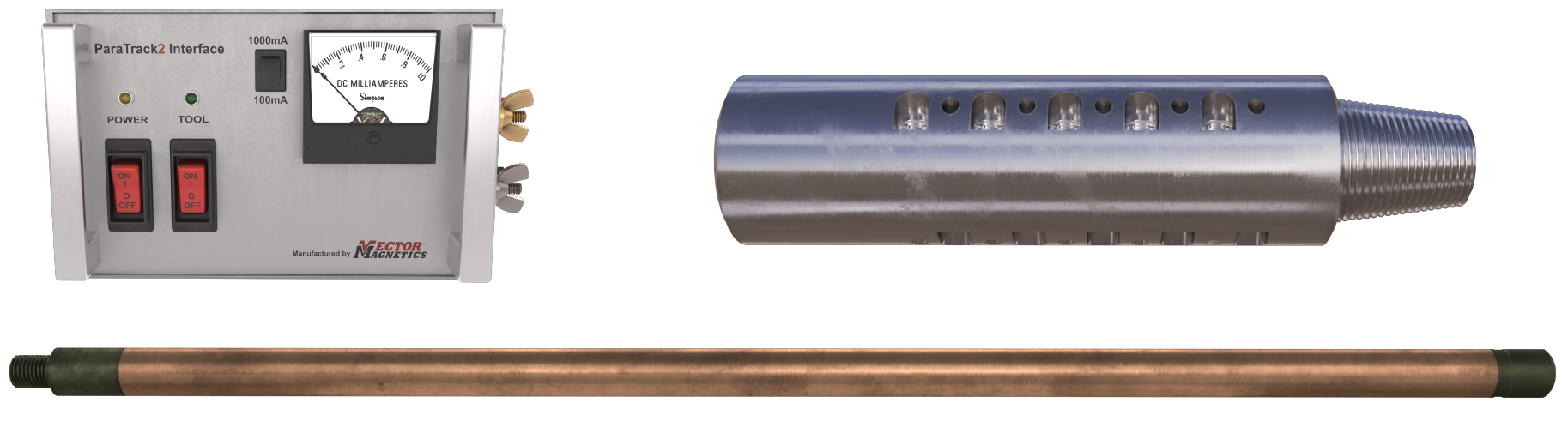

The Rotating Magnet Ranging System (RMRS) is a stand-alone active magnetic ranging tool providing independent proximity measurements free from the inaccuracies inherent in standard magnetic and gyro surveying methods.

A compact magnetic sub located directly behind the drill bit generates an AC magnetic wave form when rig pumps are activated and mud is flowing. This signal is detected by sensors in an adjacent well or HDD pilot bore, at a range of >300 ft. By verifying target location early, the driller is given adequate time to make even significant changes in trajectory. Thus, the intersection of casing as small as 4 inches in diameter is possible, without the need for a costly passby and sidetrack, saving rig time and controlling project costs.

USE CASE

SALT, POTASH, TRONA SOLUTION MINING

Customers across the globe have turned to the Rotating Magnet Ranging System to increase production and minimize costs in the development of their in-situ and solution mining operations.

HOW IT’S DONE

RMRS enables multiple caverns to be connected in series by means of single horizontally drilled production well, increasing the viability of deposits that were otherwise out of reach or otherwise not economically viable.

USE CASE

COAL BED METHANE

Coal mining operations have relied on the Rotating Magnet Ranging System for nearly two decades to improve their CBM production efficiency. Whether to de-gas the seam for safety prior to long wall mining, or to produce valuable gas from seams that are too thin, too deep, or otherwise inaccessible, RMRS improves the ROI of mining investments.

HOW IT’S DONE

The Rotating Magnet enables the precise connection of multiple vertical sumps via a single cost-effective lateral following the coal seam. The dewatering process is improved, and production equipment is concentrated at a single location.

USE CASE

HDD INTERSECTIONS

The Rotating Magnet Ranging System enables civil engineers to design expansive crossings under waterways, sub-sea canyons, major highways and infrastructure beyond the scope of even a maxi-sized HDD rig.

HOW IT’S DONE

The RMRS sub is placed behind the drill bit on one side of the crossing. Tool sensors located in the assembly of a second rig located on the opposite side detect the generated signal as the two bores approach, guiding the two drills to “meet in the middle.”