Calm Under Pressure

The risk of inadvertent returns – and the associated liability – presents significant challenges to the HDD industry.

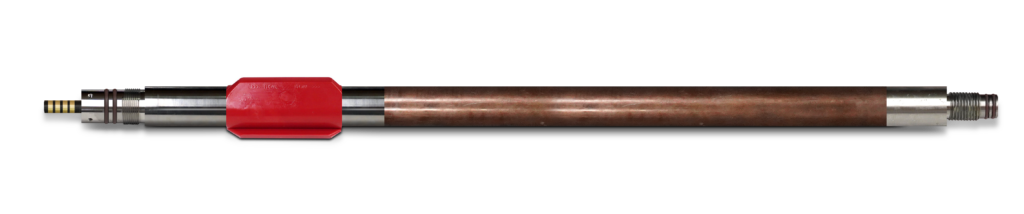

The ParaTrack Pressure Module provides the real-time information required to spot and address potential issues early. Continuous pressure data is recorded and stored in the RivCross job database, documenting that pressure limits have not been exceeded.

Improve Data Visibility

Pressure data is transmitted through a user-configurable Driller’s Display app. The app is natively compatible with any web browser, eliminating the need for expensive proprietary hardware.

Benefits

- Reduces the risk of inadvertent returns

- Logs both pipe and annular pressure

- Extends equipment service life

Applications

- HDD pilot bore logging

The ParaTrack Pressure Module is part of the complete line of ParaTrack HDD guidance tools. Available exclusively from your Inrock or Prime Horizontal dealer.

Related Posts

Nuts and Bolts of Guidance

Horizontal Directional Drilling (HDD) continues to experience rapid growth with proven effectiveness across a diverse range of installations. HDD is an essential part of the expansion and replacement of …

World Record Dual HDD Intersects in India

Numaligarh Refinery Limited (NRL) is in the process of laying a 1635km cross country pipeline from Paradip Port in Odisha to their refinery Numaligarh, Assam, India. The pipeline is proposed to run from …