CASE STUDY

PARALLEL BORES

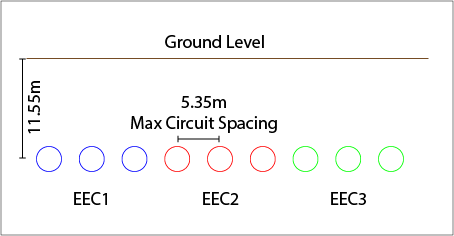

NINE BORES PLACED IN PARALLEL

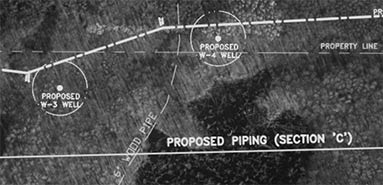

Multiple power lines from a major off-shore wind installation needed to be run in parallel under a railway within a narrow right of way in order to connect to the inland power distribution station.

ParaTrack was the system of choice for this crossing, with the initial bore guided via a ParaTrack2 Guide Wire on surface. Subsequent bores were then guided by a P2 Guide Wire run through the immediately adjacent bore, allowing for the most precise spacing along the entire crossing span.

In total 9 bores were drilled successfully within project tolerances, and ParaTrack allowed this project to occur quickly and cost-effectively, with no specialized equipment or personal required.

ParaTrack. Unparalleled in HDD crossings. Worldwide.

CASE CHALLENGES

- Nine bores in a narrow right of way required precision tolerances from entry to exit.

- Budgetary constraints demanded cost effectiveness from the contractor