ParaTrack HDD Guidance

Parallel 20″ Water Main Replacement to Tolerances No Competing Guidance System Could Meet

The Challenge

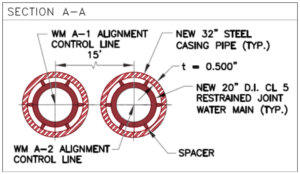

A municipality required the replacement of a pair of 100-year old unlined cast iron water mains. In their place new 20” ductile iron would be run inside 32” steel sleeves.

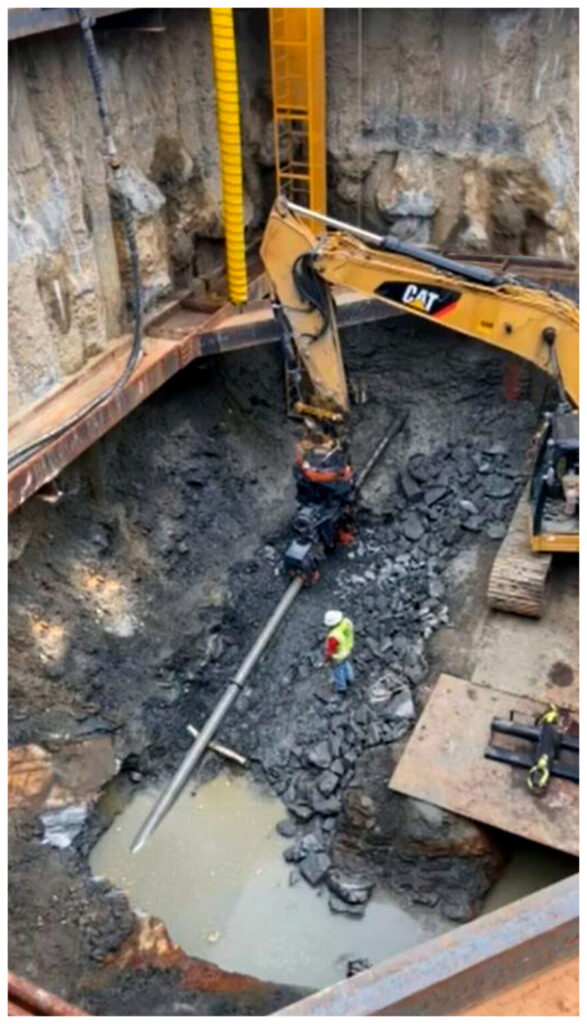

Strict design tolerances dictated that the two lines be run parallel to one another with just 15’ of centerline separation, while making a continuous horizontal curve, with the exit point restricted to a 1’ square window. Further, the contract provided no allowance for departure from the design radius of 5,500’ despite an extremely hard (compressive strength of 25,000 psi) fractured gneiss formation that found the contractor often steering right in order to hold the required left bend radius.

A complete review of available HDD guidance methods determined that only ParaTrack HDD Guidance operated by Inrock would be capable of ensuring the pilot bores met design tolerances.

A complete review of available HDD guidance methods determined that only ParaTrack HDD Guidance operated by Inrock would be capable of ensuring the pilot bores met design tolerances.

The ParaTrack Solution

With magnetic interference a known factor, ParaTrack Gyro Guidance was selected to steer the bore. As the strict tolerances were beyond the accuracy capabilities of any gyro steering tool alone, position was verified by a sunken ParaTrack2 Guide Wire that spanned the entire crossing length. With each ParaTrack2 verification shot taken completely indepent of the downhole surveys made at the steering tool, bit position could be guaranteed to the highest accuracy level possible.

As the contracted plan allowed for zero deviation from radius, the At-Bit Inclination Assembly (ABIA) was run to closely track bit elevation before a costly break in radius could occur. The only tool of its kind available to the Horizontal Directional Drilling market, the ABIA was critical in controlling elevation during the final build phase to ensure successful exit within the allowed 1’ window.

As the contracted plan allowed for zero deviation from radius, the At-Bit Inclination Assembly (ABIA) was run to closely track bit elevation before a costly break in radius could occur. The only tool of its kind available to the Horizontal Directional Drilling market, the ABIA was critical in controlling elevation during the final build phase to ensure successful exit within the allowed 1’ window.

Laydown area constraints and the need to minimize bend-over support for the steel pipe during installation led to extremely shallow entry and exit angles of just 8 degrees. With a minimum cover depth of just 5’ while passing under a tidal bay, it was critical to closely monitor annular pressure in order to eliminate the possibility of any frack out into the waterway. A ParaTrack Pressure Module transmitted pressure data in real time to both local and remote displays, while logging that continuous data stream into the permanent RivCross Guidance Management software database which was provided to inspectors to prove compliance.

ParaTrack’s unique ability to provide accurate gyro guidance whose position calculations can be independently verified with great precision enabled Horizontal Directional Drilling to succeed as the method of choice for this extremely challenging installation.

Highlights

Total Length:

2,070 ft

Entry Angle:

8°

Exit Tolerance

1 ft square